新聞中心

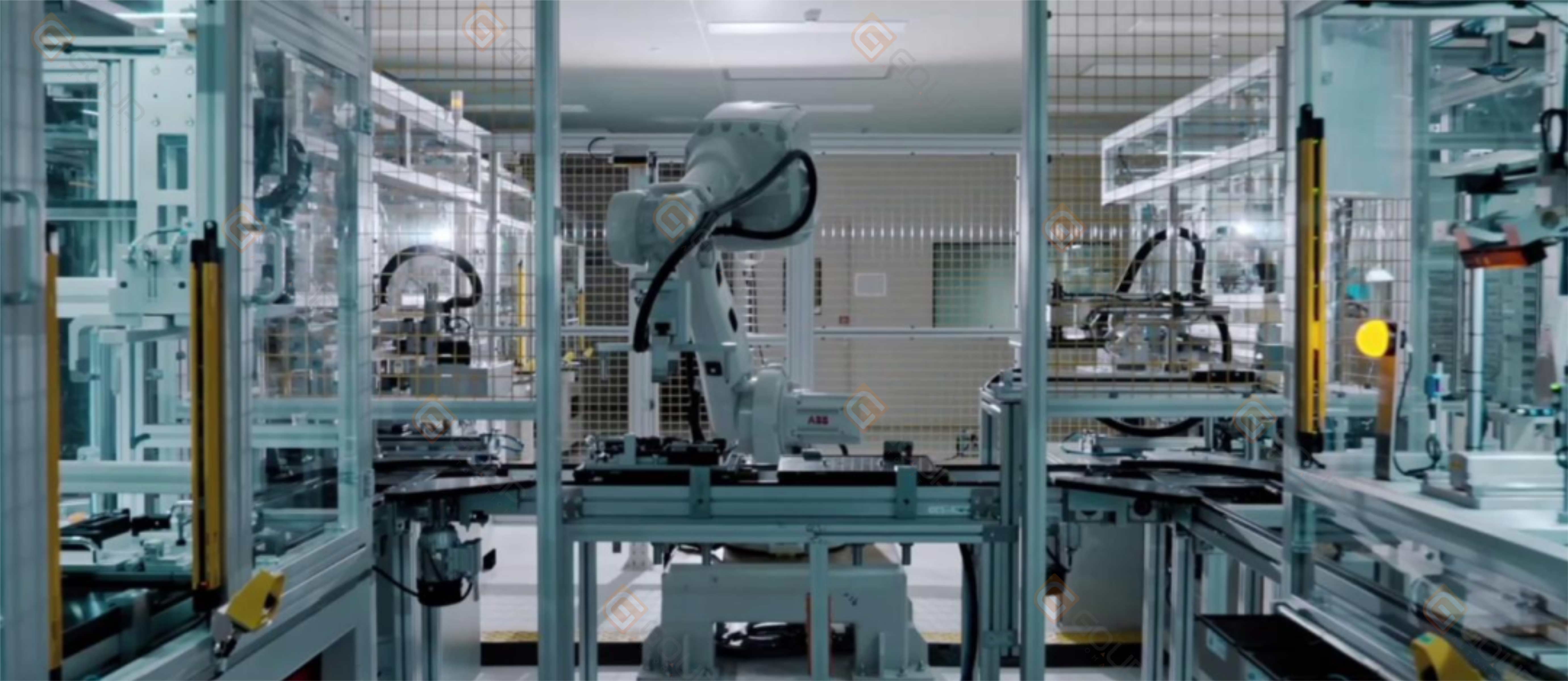

The Falcon LiDAR assembly testing line is a significant achievement in our company's automation equipment production line. The successful implementation of this project is a result of our team's relentless efforts and deep understanding of lean production principles.

1、Modular Design and Multi-Product Compatibility: The Falcon assembly testing line features a highly modular design, allowing each work stage to operate independently, which reduces the risk of production interruptions due to failures in individual stages. Additionally, the production line offers excellent multi-product compatibility, accommodating different models of LiDAR for assembly and testing needs, thereby enhancing the flexibility and applicability of the production line.

2、Application of Advanced Technologies: The project incorporates advanced technologies such as thermal adhesive coating, fiber optic splicing with UV curing, window sealant application and pressing, assembly, and leak testing. These technologies effectively improve product assembly quality and production efficiency. In particular, the use of fiber optic splicing and UV curing technology enhances the precision and stability of the optical component assembly in LiDAR, laying a solid foundation for product performance improvements.

3、Whole Line MES Control and Data Traceability: The Falcon production line utilizes comprehensive MES control, enabling real-time data collection and monitoring to promptly identify and address issues during production, thus enhancing the stability and reliability of the line. Additionally, data traceability supports quality management and continuous improvement, allowing for more precise analysis and optimization of the production process.

During the project implementation, we realized that continuously advancing the standardization of organizational and procedural design is crucial for enhancing production efficiency and quality management. Therefore, we are committed to further improving our internal management systems and promoting the standardization and automation of production processes.

We believe that with ongoing technological innovation and enhanced company management, our competitiveness in the automation equipment production line sector will be further strengthened, allowing us to provide even higher quality products and services to our clients.